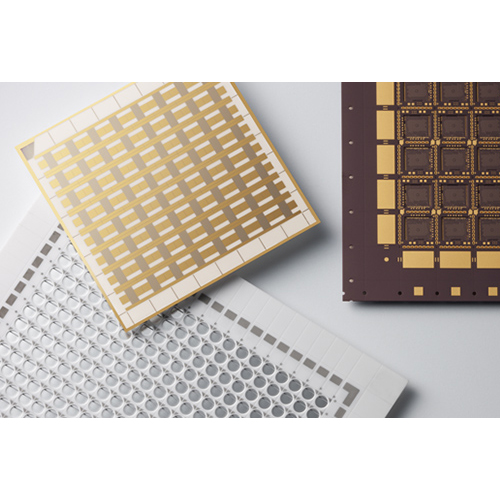

Metallized Ceramic Substrates

Metallized Ceramic Substrates

- MARUWA

- ±50㎛

1.Thickness: 0.1㎜~1.5㎜ / 4mil~60mil

2.Cutting Accuracy: ±50㎛

Features

Submounts have been developed by combining metallization and ceramic material technologies which MARUWA has cultivated for many years. The materials can be customized with various pattern technologies, such as wraparound metallization. This product is used in circuit substrates for optical storage, optical communication, RF application, and various other uses.

Metallization General Specification

| Item | Standard Specification | ||

| Substrate Material | Material | Alumina(Al2O3) | 99.5%、96%etc. |

| Aluminum Nitride(AlN) | - | ||

| Dielectric Substrate | ε38、ε93etc. | ||

| Thickness | 0.1㎜~1.5㎜ / 4mil~60mil | ||

| Work Size | 50.8㎜□(2inch□)、2inch × 4inch□、3inch | ||

| Film Specification (Conductor) | Film Composition / Film Thickness | Dry Etching | Ti/Pt/Au=0.06/0.2/0.3㎛~2.0㎛approx |

| Ti/Pd/Au=0.06/0.2/2.0㎛~10.0㎛approx | |||

| Wet Etching | Ti/Pd/Au=0.06/0.2/2.0㎛~10.0㎛approx | ||

| Film Specification (Resistance Body) | Seat Resistance | 25Ω/□、50Ω/□(±20%) | Special Specification (±5%) |

| T.C.R | -50±50ppm/°C | ||

| Film Composition | Tantalum Nitride(Ta2N) | ||

| Film Specification (Solder) | Film Composition / Film Thickness | Au/Sn | 1.5㎛~10㎛ |

| Processing Specification (Thin Film Circuit) | Minimum Line & Space | Dry Etching | L/S≧10㎛ |

| Wet Etching | L/S:20㎛/20㎛±10㎛ | ||

| Processing Specification (Machining) | Cutting Accuracy | ±50㎛ | |

| Item | Inspection Item | Measurement Inspection Machines |

| Quality Assurance | Size | Measuring Microscope |

| Film Thickness | X-ray Fluorscence, Surface Rough Meter | |

| Resistance | Digital Multi Meter | |

| Externals | Microscope | |

| Wire Strength | Pltester |